AI-based quality control tools enhance product consistency. We optimize supply chains for efficiency, reducing costs. AI-driven production process analysis identifies inefficiencies, boosting productivity. Invex.ai also provides robotics and automation solutions for precise and safe manufacturing.

Predictive Maintenance

Invex.ai’s AI-driven predictive maintenance systems analyze data from sensors and equipment to predict when machinery is likely to fail. This allows for proactive maintenance, reduces downtime, and optimizes production efficiency.

Quality Control and Defect Detection

AI-powered computer vision systems inspect products on the manufacturing line for defects, ensuring consistent quality and reducing waste. These systems can identify defects in real-time, improving overall product quality.

Supply Chain Optimization

Invex.ai optimizes manufacturing supply chains using AI algorithms to manage inventory levels, streamline logistics, and minimize transportation costs. This improves efficiency and reduces operational expenses.

Production Process Optimization

AI-based systems continuously analyze manufacturing processes to identify inefficiencies and areas for improvement. This data-driven approach enhances productivity and reduces resource consumption.

Robotics and Automation

AI-driven robots and automation systems perform complex manufacturing tasks with precision and speed. This technology increases production capacity, reduces errors, and improves safety in manufacturing facilities.

Energy Management

AI-based energy management systems monitor and control energy usage in manufacturing plants. These systems optimize energy consumption, reduce costs, and minimize the carbon footprint of manufacturing operations.

Inventory Forecasting

Invex.ai’s AI models analyze historical sales data and market trends to forecast demand accurately. This helps manufacturers maintain optimal inventory levels, reduce excess stock, and minimize holding costs.

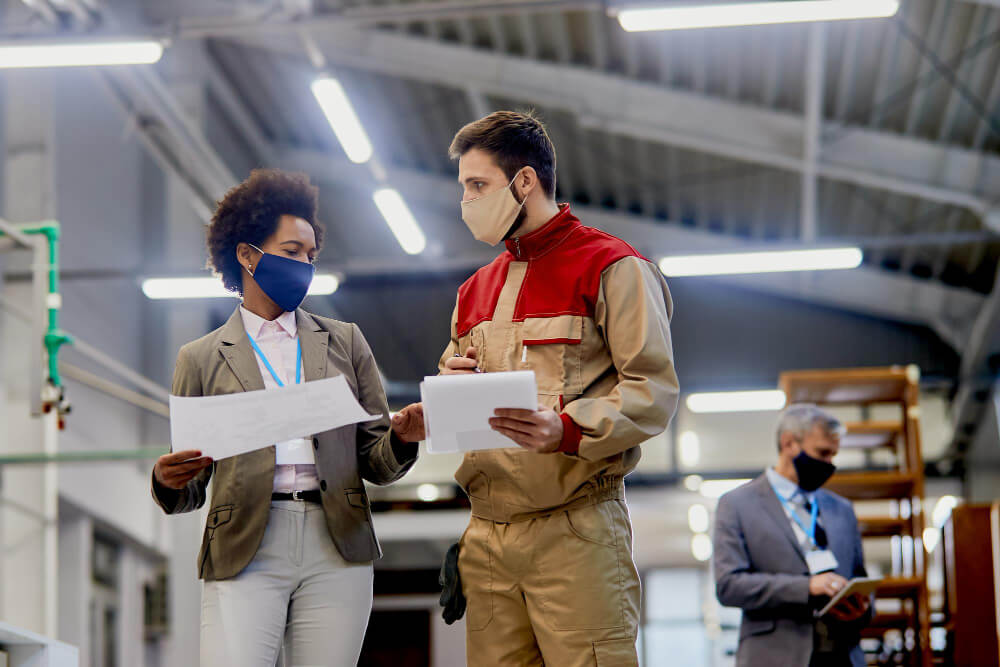

Human-Robot Collaboration

AI facilitates safe and efficient collaboration between human workers and robots on the factory floor. This collaborative approach enhances worker productivity and allows robots to handle repetitive or dangerous tasks.

Product Lifecycle Management

AI assists in managing the entire product lifecycle, from design and prototyping to production and maintenance. This streamlines product development processes and ensures product quality and reliability.

Supply Chain Visibility

AI-driven supply chain visibility tools provide real-time tracking and monitoring of inventory, shipments, and supplier performance. This improves transparency, reduces delays, and enhances overall supply chain efficiency.